Improved moisture resistant board

- Suitable for single-layer steel stud and cavity shaftwall systems, lesson labor and material costs using fewer layers (up to 10%).

- Type X core is fire resistant and an approved component in UL fire-rated designs.

- Mold and moisture resistant, fights the effects of moisture before damage can occur.

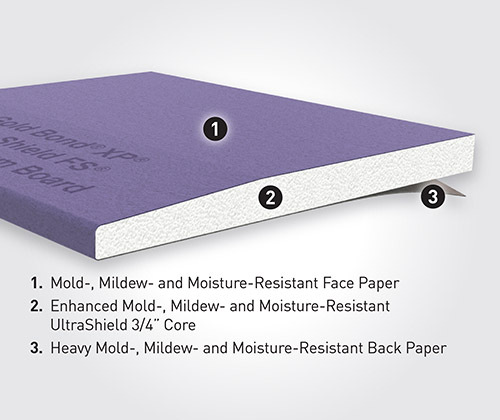

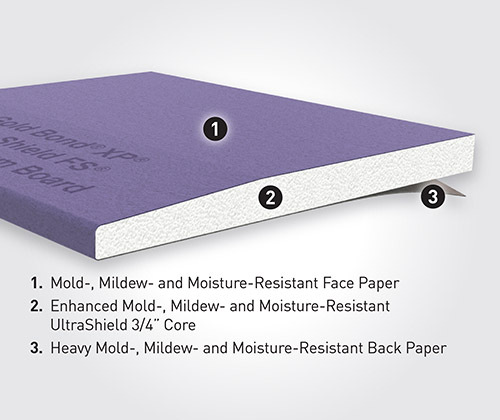

Gold Bond® XP® Ultra-Shield FS® Gypsum Board is 3/4" thick and consists of a mold-, mildew-, moisture- and fire-resistant gypsum core encased in 100% recycled paper on the face and back sides. The PURPLE® face paper is folded around the long edges to reinforce and protect the core, and the ends are square cut and finished smooth.

Use it for 2- and 3- hour wall partitions and 2-hour cavity shaftwall assemblies to reduce material and installation labor. The core allows one layer of 3/4“ XP Ultra-Shield FS to replace two layers of 5/8“ Type X, or two layers of 3/4“ XP Ultra-Shield FS to replace three layers of 5/8“ Type X, in specific UL assemblies.

GridMarX® are printed on the face paper surface to help installers identify stud locations and make accurate cuts without having to pencil in or snap chalk lines.

Check the Fire and Safety Information for a more complete explanation of how fire resistance ratings work.

APPLICATIONS:

- For single-layer – steel stud and cavity shaftwall systems. The greater thickness provides increased resistance to fire and reduced sound transmission vs. a single layer of 5/8” Type X.

- Can be used as a tile backer board in dry areas or areas with limited water exposure such as toilet/sink areas.

ADVANTAGES:

PROVIDES ADDITIONAL FIRE RESISTANCE

- Features a Type X core making it more fire resistant than ordinary wallboard.

- Approved component in specific UL fire-rated designs.

- The gypsum core will not support combustion or transmit temperatures greatly in excess of 212°F (100°C) until completely calcined, a slow process.

- UL Classified for fire-resistance and surface burning characteristics.

MOLD, MILDEW AND MOISTURE RESISTANT

- Helps inhibit mold growth with the highest possible score on mold tests (ASTM D3273 and ASTM G21).

- Features SPORGARD® technology with extra mold-inhibiting properties.

- Fights the effects of moisture before damage can occur.

- Dimensionally stable product with negligible expansion and contraction under normal atmospheric conditions.

- Has less than 5% water absorption per ASTM C473.

RESISTS ABUSE

- Thicker core equals added abuse resistance.

INSTALLS FAST AND EASY

- Features GridMarX guide marks on the board to allow for faster more accurate installation.

- Save time and money with MaX 12® and MaX 16® optimized fastener patterns to achieve 1-hour fire ratings using fewer fasteners.

- Lesson labor and material costs by using fewer layers (up to 10%).

- Scores and snaps easily and cuts quickly, permitting painting or other decoration and the installation of metal or wood trim almost immediately.

LOW-EMITTING MATERIALS

- Qualifies as a low-VOC emitting material by meeting California Specification 01350.

- Achieves UL GREENGUARD Gold Certification for low chemical emissions into indoor air during product usage. For more information, visit: ul.com/gg.

Specifications

Products that suit any project criteria

Product Details

Performance:

Mold & Moisture Resistant, Drywall Panels

Edge(s):

Tapered

Thickness(es):

3/4"

Width(s):

48"

Related Resources

Product details and technical documentation

Tips & Tools

Helpful resources for your next project

Compare Products

Drywall Panels

Gold Bond® XP® Ultra-Shield FS® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

Product Family

XP

Application

- Multifamily

- Interior Walls & Ceilings

- Shaftwall Systems

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified

Description

For single layer - steel stud and cavity shaftwall systems.

Drywall Panels

Gold Bond® EVOLVE XP™ Fire-Shield® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Lightweight Panels

Product Family

XP, EVOLVE

Application

- Single-Family

- Multifamily

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified

Description

Up to 20% lighter than 5/8" XP® Fire-Shield® Gypsum Board with lower environmental impact

Drywall Panels

Gold Bond® SoundBreak® XP® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Ceiling Board / Panels

- Acoustical

Product Family

SoundBreak, XP

Application

- Multifamily

- Single-Family

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified

Description

For interior, non-fire rated wall and ceiling assemblies, where sound transmission between rooms or dwelling units is a concern.

Drywall Panels

Gold Bond® SoundBreak® XP® Fire-Shield® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Ceiling Board / Panels

- Acoustical

Product Family

SoundBreak, XP

Application

- Single-Family

- Multifamily

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified, HPD - Health Product Declaration, EPD - Environmental Product Declaration

Description

For interior, fire-rated, wall and ceiling assemblies, where sound transmission between rooms or dwelling units is a concern.

Drywall Panels

Gold Bond® SoundBreak® XP® Fire-Shield C™ Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Ceiling Board / Panels

- Acoustical

Product Family

SoundBreak, XP

Application

- Multifamily

- Single-Family

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified

Description

Apply to wall and floor-ceiling assemblies where airborne sound transmission and structurally transmitted sound are a concern.

Drywall Panels

Gold Bond® SoundBreak XP Retrofit® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Acoustical

Product Family

SoundBreak, XP

Application

- Multifamily

- Single-Family

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified

Description

Improve the acoustical performance of an existing wall assembly.

Drywall Panels

Gold Bond® XP® Hi-Abuse® Gypsum Board

Product Type

- Drywall Panels

- Mold & Moisture Resistant

- Abuse & Impact Resistant

Product Family

XP

Application

- Multifamily

- Single-Family

- Interior Walls & Ceilings

Sustainability

GREENGUARD Certified, GREENGUARD Gold Certified, HPD - Health Product Declaration, Declare Labels

Description

Ideal for use in wall assemblies where surface abrasion is a concern.

Design & Resource Center

Browse our digital library of tools, resources, and service options to support your team.

Learn More

Expert Connection

Gold Bond experts are ready to discuss project and product needs to meet your goals.

Expert ConnectionNeed Technical Information?

Call 1-800-NATIONAL®

National Gypsum Company is the exclusive service provider for products manufactured by Gold Bond Building Products, LLC.